Services

Bitumen Mastic

We

offer impermeable, durable and deformation resistant

bitumen mastic. Our bitumen mastic is a homogeneous

mortar, which is a mixture of high-grade bitumen,

mineral fillers and fine aggregates. Its consistency

is such that it flows like highly viscose fluid

at a temperature of about 200 degree Celsius but

on cooling down it becomes hard.

Mastic

Asphalt Over Bituminous Cement Concrete Base

Types

of Bitumen Mastic

|

Bitumen

mastic for flooring |

-

IS: 1195-1978 |

|

Bitumen

mastic for Waterproofing of roofs |

-

IS: 3037-1965 |

|

Bitumen

mastic for bridge decking and roads |

-

IS: 5317-1969 |

|

Bitumen

mastic for tanking and damp-proofing |

-

IS: 5871-1970 |

|

Bitumen

mastic anti-static & electrically conducting

grade |

-

IS: 8374-1977 |

|

Bitumen

mastic-acid resistance grade |

-

IS: 9510-1980 |

|

Bitumen

mastic for waterproofing and protective coating

for concrete slabs. |

|

|

Black

pitch, mastic flooring (Oil resistant) |

|

Composition

of Mastic

| Bitumen

blown grade |

:

9%-10% |

| Lime

stone dust (filler) |

:

20% |

| Aggregated

and dust |

:

70% |

Materials

Required

- Blown

(Industrial Grade) bitumen

- Softening

Point 55 degree C to 75 Degree C

- Penetration

at 25 degree C in 1/100 cm 10 to 40

- Limestone

dust with calcium carbonate content exceeding

80%

- Crusher

dust

- Aggregate

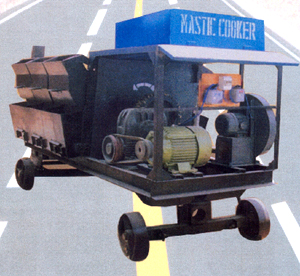

Equipment

Required

- Bitumen

Mastic Cooker with mechanical agitation system

mounted on wheels.

- Tar

Boiler for heating bitumen.

- Wooden

spreading and finishing floats.

- Wooden

Forms.

- Mastic

pouring bucket/wheel barrows as per requirement.

- Hand

hammers for anti-skid.

Methodology

Adopted

- The

surface is cleaned with wire brush/broom.

- Tack

coat is applied.

- The

first stage shall be mixing of filler and fine

aggregates and then heating the mixture to a temperature

of 170 degree C to 210 degree C.

- Bitumen

is heated separately at a temperature of 170 degree

C to 180 degree C and then mixed with pre-heated

ingredients in the cooker.

- The

2nd stage is incorporation of coarse

aggregate and cooking the mixture for appropriate

time to ensure that the contents in the cooker

are at no time heated to a temp. exceeding 210

degree C.

- The

mixture is laid at site by the labour manually.

- To

control the thickness of the laid mastic, wooden

forms are used.

Structure

Works Structure

Works

Culvert

is defined as a tunnel structure constructed under

roadways or railways to provide cross drainage or

to take electrical or other cables from one side

to other. It is totally enclosed by soil or ground.

Pipe culvert, box culvert and arch culvert are the

common types used under roadways andrailways.

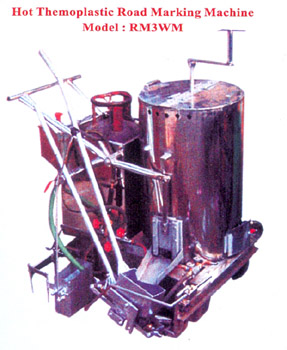

Thermoplastic Road Marking Paint

Thermoplastic

Road Marking Paint (TRMP)

The Company uses TRMP conforming to the specifications

laid down by the Ministry of Surface Transport (803.4)

Methodology

and Application Procedure:

- The

surface should be free from moisture.

- Dust,

grease and any foreign matters are cleared off

from the surface of the road to be marked.

- Previous

old paint marking is removed by wire brushes before

application.

- The

compound is pre-heated to around 180 degrees (+/-10ºC)

and transferred in application machine. Glass

beeds are super-imposed through a dispenser or

manual spray as per MOST specifications. Suitable

marking compound is applied on the concrete.

- Moslten

TRMP is applied on the surface using Paint Applicators

fitted with glass beed dispenser.

- TRMP

is laid only after marking is done.

- Suitable

primer is applied when TRMP is to be applied to

concrete surfaces.

- Temperature

of application with this machine is maintained

in the range of 180º to 200ºC.

- Drops

of glass beeds conforming to BS 6088 type B are

sprayed while the paint through glass beeds gun

attached with the paint applicator @250gms. Per

sq. Mtr. Recommended coverage is 5 kg, TRMP per

sq. Mtr on smooth surface at 2.5 mm thickness.

- As

per specifications the dying time of paint is

8m to 10 minutes based on the temperature.

To

avoid personal hazards, special care is taken for

workers safety and arrangements of first aid are

made at Site.

Road Furniture and Road Signages

We

fabricate road signs that conform to IRC 67-2012

Rules. All basic and modern road signs are fabricated.

These are made from durable materials and are painted

in bright colours which can be seen from long distances.

We specialize in fabricating Delineator Posts, Cautionary

sign, Overhead Gantry, Directional - Informatory,

Cantilever and facility information sign boards.

We also undertake other road safety/road furniture

works like fixing of RPMs (Road Studs), Delineators,

Bollards etc. on the State/National Highways.

|